Kugwiritsa ntchito thermoelectric module (yomwe imadziwikanso kuti thermoelectric cooling modules, TEC, kapena Thermoelectric Cooler) mu chipangizo chobwezeretsa khungu la photon makamaka ndi cholinga chokwaniritsa ntchito yoziziritsa, kuti chitonthozo ndi chitetezo chikhalepo panthawi ya chithandizo. Nayi kufotokozera mwatsatanetsatane kwa thermoelectric cooling modules, thermoelectric modules, TECs, peltier modules mu chipangizo chobwezeretsa khungu la photon:

1. Mfundo yogwirira ntchito

Gawo la thermoelectric limachokera ku zotsatira za Peltier: Pamene mphamvu yolunjika imadutsa mu thermoelectric pair yokhala ndi zinthu za semiconductor za mtundu wa N ndi P, mbali imodzi imatenga kutentha (kumapeto kozizira) ndipo mbali inayo imatulutsa kutentha (kumapeto kotentha). Mu chipangizo chobwezeretsa khungu cha photon:

Malekezero ozizira ali pafupi ndi khungu kapena kristalo wotsogolera kuwala, womwe umagwiritsidwa ntchito poziziritsa

Mapeto otentha amalumikizidwa ku sinki yotenthetsera (monga fani kapena makina oziziritsira madzi), kuti atulutse kutentha.

2. Ntchito zazikulu mu chipangizo chobwezeretsa khungu la photon. Tetezani khungu

Kuwala kwamphamvu kwambiri (IPL) kapena kuwala kwa laser kumabweretsa kutentha, komwe kungayambitse kupsa kapena kusasangalala. Choziziritsiracho chingachepetse kutentha kwa khungu mwachangu ndikuchepetsa chiopsezo cha kuwonongeka kwa kutentha.

Sinthani chitonthozo

Kuzizira kumeneku kumatha kuchepetsa ululu kapena kutentha komwe kumachitika panthawi ya chithandizo, zomwe zimapangitsa kuti wogwiritsa ntchito azitha kusangalala.

Limbikitsani kugwira ntchito bwino

Pambuyo poti khungu la khungu lazizidwa, mphamvu imatha kukhazikika kwambiri pa minofu yomwe ikufunidwa (monga ma follicle a tsitsi, maselo a pigment), zomwe zimapangitsa kuti ntchito ya photothermal igwire bwino ntchito.

Pewani kuwononga utoto

Kuwongolera kutentha bwino kungachepetse chiopsezo cha hyperpigmentation pambuyo pa opaleshoni (PIH), makamaka kwa anthu omwe ali ndi khungu lakuda.

3. Njira Zodziwika Zokonzera

Kuziziritsa kwa zolumikizira: Choziziritsiracho chimakhudza khungu mwachindunji kapena kudzera pawindo la safiro/silicon.

Kuziziritsa kosakhudzana ndi kukhudzana: Kuphatikiza ndi thandizo la mpweya wozizira kapena gel, koma kuziziritsa kwa semiconductor kumakhalabe gwero lalikulu la kuziziritsa

TEC ya magawo ambiri, gawo la thermoelectric la magawo ambiri: Zipangizo zapamwamba zingagwiritse ntchito ma cooling pad angapo kuti zichepetse kutentha (monga 0-5℃)

4. Zodzitetezera

Kugwiritsa ntchito mphamvu ndi kutayira kutentha: Peltier module, TEC module imafuna mphamvu yayikulu, ndipo kutentha kuyenera kukhala ndi kutayira kutentha kogwira mtima; apo ayi, mphamvu yozizira idzatsika kwambiri kapena kuwononga chipangizocho.

Vuto la madzi oundana: Ngati kutentha kwa pamwamba kuli kotsika kuposa mame, madzi oundana angapangidwe, ndipo chithandizo chosalowa madzi/choteteza chikufunika

Moyo ndi kudalirika: Kusintha pafupipafupi kapena malo otentha kwambiri kudzafupikitsa moyo wa gawo la TEC. Ndikofunikira kugwiritsa ntchito zida zamagetsi.

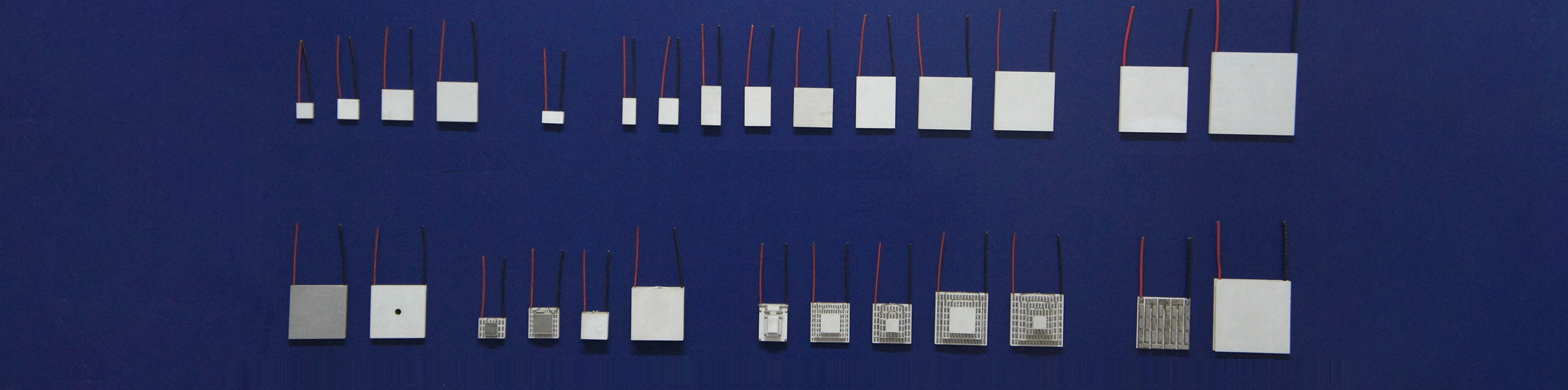

Kufotokozera kwa TES1-17710T125

Kutentha kwa mbali yotentha ndi 30 ° C,

Imax: 10.5 A,

Mphamvu yamagetsi: 20.9V

Qmax: 124 W

ACR: 1.62 ± 10% Ω

Delta T max: > 65 C

Kukula: pansi 84 × 34 mm, pamwamba: 80x23 mm, kutalika: 2.9 mm

Dzenje lapakati: 60x 19 mm

Mbale ya Ceramic: 96%Al2O3

Chotsekedwa: Chotsekedwa ndi 703 RTV (mtundu woyera)

Chingwe: 18 AWG kutentha kwa waya kukana 80℃.

Kutalika kwa chingwe: 100mm, waya ndi tini yokhala ndi solder ya Bi Sn, 10mm

Zipangizo zamagetsi: Bismuth Telluride

Nthawi yotumizira: Januwale-14-2026